Northeast

Implement

Products

Check Our Our Other Brands!

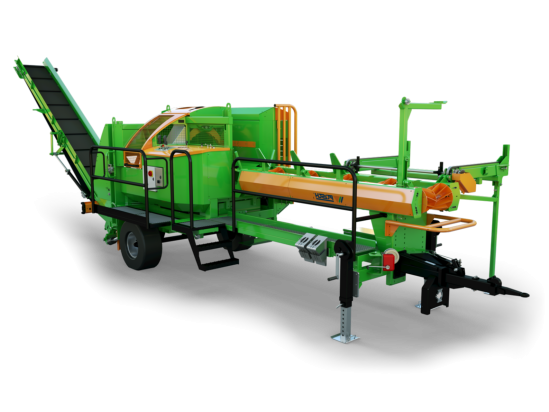

SpaltFix K-440

Split cutting for professionals

It is no longer possible to imagine professional firewood production without our powerful cut splitters. Stationary

or mobile – they adapt perfectly to the requirements for large volumes. The SpaltFix K-440 processes logs with a

diameter of up to 45 cm. With the wide variety of drives and additional solutions, it helps you to make wood

processing faster and more efficient.

19.84 t

splitting power max.

17.72 in

Log ∅ max.

12 billets

per work cycle max.

SpaltFix K-440

Overview

Log Charging

Optimum Charging For

Better Hourly Output

Roller Conveyor

Helps you to get even more

work done. For the SpaltFix K, a

wide variety of log conveyor

systems can be combined with

each other to create a customized

solution. For mobile systems,

integrated charging systems that

put the logs on working height

are available.

Log Support Systems For

Large Volumes

A suitable timber support system

receives a larger number of logs in

every work cycle. The logs are put

down by means of a forklift truck or

timber loading crane and made

available for further processing.

When they are passed on from all

timber support systems to the roller

conveyor, the logs are automatically

separated from each other by

different systems, for example step

conveyors or cross conveyors, and

so can be processed bit by bit. The

optional cleaning belt transports the

scrap wood underneath the cross

conveyor in the right container.

LogDeck & LogSep

The LogDeck is the ideal

professional solution for very

large volumes of timber.

Depending on the design, up to

60 m³ of timber can be placed

directly on the cross conveyor.

The separator LogSep ensures

optimum separation and transfer

to the longitudinal conveyors.

Drives and Chassis

Ready For Every Task

With the different drive variants PTO, E-motor or diesel, the SpaltFix is always

well-equipped and also suited for mobile applications. For mobile applications,

the optional elbow conveyor belts ensure a compact transport position. The

different chassis models with integrated log charging ensure that the SpaltFix K

is quickly ready for use. The optionally available hydraulic support feet ensure

vertical stability. Integrated cross conveyors are put in the work position

manually or hydraulically.

Drive By Diesel Engine

Various Chassis Types

Are Available

Special Equipment

More power for the SpaltFix K-440

Versatile and sturdy, the frame knives adapt to the respective application. The

double-edged knife produces smooth splitting edges, the ring knife variants

produce many uniform billets that are ready for the stove in one work cycle.

The hydraulic splitting knife adjustment ensures splitting in the middle with

every log diameter. With the 3-in-1 splitting knife functionality, you can always

choose the best tool without knife change. Directly before the splitting stroke,

the optical sensor measures the log diameter, selects the ideal area of the special

splitting knife and centers it.

3-in-1 Frame Knife

SplitControl

This is what the automatic system

does for you:

•

Improved firewood quality due

to more uniform billets

•

Less splitting power required and

less strain on machine

•

Higher user-friendliness

Additionally Integrated:

SplitControl also determines the

processed wood volume in solid

cubic meters. The timber volume

measurement is only intended for

internal use.

Packaging

Drying, storing and delivering firewood in the perfect packaging

The PackFix system is a fast and efficient solution for packing up billets and

ensures fast drying of the billets produced. Thanks to the tilting table, the

conveyor belt standstill is minimized and firewood production runs without

interruption with the 2-drum solution.

PackFix Hydro

PackFix Hydro With

Tilting Table

Copyright © 2016 Northeast Implement

Northeast Implement

&